Understanding your car's tyres - all you need to know

26 May 2023|7,776 views

The importance of tyres to a vehicle can never be exaggerated - they are the only points of contact that your car has with the road and are the sole determinant of whether your car will stay on the road, or slide off it, into an accident.

Hence, it can only be beneficial to learn more about these black, round things that have such an important role in keeping us safe and in control when driving down the roads. So here's a comprehensive guide on everything you'll want to know about tyres, starting from how they are made.

How a tyre is made

There are five major stages in the manufacturing process of a tyre: Blend, Mill, Build, Cure and Inspect.

1. Blend:

While we all know that tyres are made of rubber, they are made of a really complex mix! The black compound that makes up the basis of a tyre are actually a combination of up to 30 different kinds of rubber, fillers and other ingredients that are mixed in giant blenders.

2. Mill:

After the blended compound has cooled, it is then cut into strips that will become the basic structure of the tyre. Other components that make up the tyre will also be prepared at this stage.

3. Build:

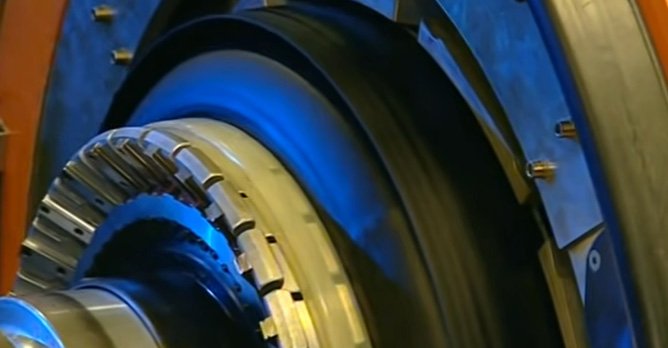

With the components prepared, the tyre can now be made! The parts such as the textile elements, steel belts, beads, ply, tread and other components are all assembled on a tyre-building machine to result in a 'green tyre' - at this stage, the tyre is starting to take shape.

4. Cure:

The 'green tyre' is now vulcanised in a curing press that compress all the parts together while giving the tyre its final shape, including its tread pattern and sidewall markings. The tyre is now completed.

5. Inspect:

The finished tyre is carefully checked by trained inspectors to ensure that it meets strict manufacturing standards before being shipped for sale.

Tread patterns and their characteristics

When we look at tyre tread patterns, we tend to look at it as a whole, but there's much more to it. A tyre tread can be broken down to four main parts - the ribs, tread blocks, grooves, and sipes.

The ribs refer to the raised section of the tread pattern - made up of tread blocks, the tread blocks are the raised rubber segments that contact the road surfaces, the grooves are the deep channels that run around the circumference of the tyre, and the sipes are the small thin slots molded into the tread blocks.

The design of each individual component of the tread pattern will affect the tyre's characteristics in terms of handling, response, wet weather performance, noise, and wear rate, among others. As you can see, tread pattern is a crucial part of tyre design.

Tyre tread patterns can be categorised into three distinct types: symmetrical, asymmetric, and directional.

Symmetrical tyres' largest advantage is the flexibility for tire rotation, and they also tend to be quiet, long-lasting and fuel efficient. These tyres, however, tend to be less effective in wet conditions.

An asymmetric tyre tread features two separate and distinct tread design on the inner and outer half of the tyre. This allows a combination of tread patterns to offer a mix of desired features. The inner tread is responsible for water displacement, while the outer tread can be designed to be offer high grip when driving hard in the dry. You'll tend to find such tread design on high-performance applications.

A directional tyre is designed to roll in one direction. Such a tread design tend to be more capable of resisting aquaplaning as it is able to displace water efficiently. These tyres tend to also provide good handling and high traction, which makes it great for performance applications as well. However, like asymmetric tyres, it will complicate the tyre rotation procedure.

Markings and indications on a tyre

You'll find some markings on the sidewall of the tyre, these typically includes the brand and model of the tyre, but it will also contain a set of important markings - the size of the tyre.

Typically, you'll see something like 215/40R17 83W, and here's how you read it:

1. Width - '215': This indicates the width of the tyre in mm

2. Aspect Ratio - '40': This indicates the aspect ratio of the tyre's sidewall (40 indicates the section height of the tyre to be 40% of its width)

3. Tyre Construction - 'R': R indicates that the tyre is of a radial ply construction

4. Rim Diameter - '17': This indicates the size of the rim in inches

5. Load Index - '83': This indicates the maximum load capacity of the tyre (the load index of 83 means the tyre can withstand a maximum load of 487kg - you'll need to refer to a chart)

6. Speed Symbol - 'W': This indicates the maximum speed the tyre is rated to (W indicates a maximum speed of 270km/h)

Another marking you'll find on a tyre is its manufacturing date: it consists of four digits, the first two will indicate the week while the next two digits indicates the year of manufacture. Typically you'll also find the treadwear, traction and temperature rating of a tyre on the sidewall - these are pretty much self-explanatory, and can be a useful reference point when comparing tyres.

*This article was first published on Sgcarmart on 1 September 2007.

The importance of tyres to a vehicle can never be exaggerated - they are the only points of contact that your car has with the road and are the sole determinant of whether your car will stay on the road, or slide off it, into an accident.

Hence, it can only be beneficial to learn more about these black, round things that have such an important role in keeping us safe and in control when driving down the roads. So here's a comprehensive guide on everything you'll want to know about tyres, starting from how they are made.

How a tyre is made

There are five major stages in the manufacturing process of a tyre: Blend, Mill, Build, Cure and Inspect.

1. Blend:

While we all know that tyres are made of rubber, they are made of a really complex mix! The black compound that makes up the basis of a tyre are actually a combination of up to 30 different kinds of rubber, fillers and other ingredients that are mixed in giant blenders.

2. Mill:

After the blended compound has cooled, it is then cut into strips that will become the basic structure of the tyre. Other components that make up the tyre will also be prepared at this stage.

3. Build:

With the components prepared, the tyre can now be made! The parts such as the textile elements, steel belts, beads, ply, tread and other components are all assembled on a tyre-building machine to result in a 'green tyre' - at this stage, the tyre is starting to take shape.

4. Cure:

The 'green tyre' is now vulcanised in a curing press that compress all the parts together while giving the tyre its final shape, including its tread pattern and sidewall markings. The tyre is now completed.

5. Inspect:

The finished tyre is carefully checked by trained inspectors to ensure that it meets strict manufacturing standards before being shipped for sale.

Tread patterns and their characteristics

When we look at tyre tread patterns, we tend to look at it as a whole, but there's much more to it. A tyre tread can be broken down to four main parts - the ribs, tread blocks, grooves, and sipes.

The ribs refer to the raised section of the tread pattern - made up of tread blocks, the tread blocks are the raised rubber segments that contact the road surfaces, the grooves are the deep channels that run around the circumference of the tyre, and the sipes are the small thin slots molded into the tread blocks.

The design of each individual component of the tread pattern will affect the tyre's characteristics in terms of handling, response, wet weather performance, noise, and wear rate, among others. As you can see, tread pattern is a crucial part of tyre design.

Tyre tread patterns can be categorised into three distinct types: symmetrical, asymmetric, and directional.

Symmetrical tyres' largest advantage is the flexibility for tire rotation, and they also tend to be quiet, long-lasting and fuel efficient. These tyres, however, tend to be less effective in wet conditions.

An asymmetric tyre tread features two separate and distinct tread design on the inner and outer half of the tyre. This allows a combination of tread patterns to offer a mix of desired features. The inner tread is responsible for water displacement, while the outer tread can be designed to be offer high grip when driving hard in the dry. You'll tend to find such tread design on high-performance applications.

A directional tyre is designed to roll in one direction. Such a tread design tend to be more capable of resisting aquaplaning as it is able to displace water efficiently. These tyres tend to also provide good handling and high traction, which makes it great for performance applications as well. However, like asymmetric tyres, it will complicate the tyre rotation procedure.

Markings and indications on a tyre

You'll find some markings on the sidewall of the tyre, these typically includes the brand and model of the tyre, but it will also contain a set of important markings - the size of the tyre.

Typically, you'll see something like 215/40R17 83W, and here's how you read it:

1. Width - '215': This indicates the width of the tyre in mm

2. Aspect Ratio - '40': This indicates the aspect ratio of the tyre's sidewall (40 indicates the section height of the tyre to be 40% of its width)

3. Tyre Construction - 'R': R indicates that the tyre is of a radial ply construction

4. Rim Diameter - '17': This indicates the size of the rim in inches

5. Load Index - '83': This indicates the maximum load capacity of the tyre (the load index of 83 means the tyre can withstand a maximum load of 487kg - you'll need to refer to a chart)

6. Speed Symbol - 'W': This indicates the maximum speed the tyre is rated to (W indicates a maximum speed of 270km/h)

Another marking you'll find on a tyre is its manufacturing date: it consists of four digits, the first two will indicate the week while the next two digits indicates the year of manufacture. Typically you'll also find the treadwear, traction and temperature rating of a tyre on the sidewall - these are pretty much self-explanatory, and can be a useful reference point when comparing tyres.

*This article was first published on Sgcarmart on 1 September 2007.